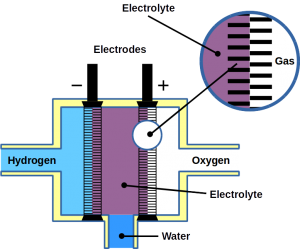

It has been known that microbial biofilms on biocathodes improve the productions rates of hydrogen evolution reaction (HER). This is the process of producing hydrogen gas from water using electricity. The hydrogen evolution was even accelerated when the biofilm colonizing a biocathode was killed. Different types of bacteria, such as exoelectrogenic (Geobacter sulfurreducens), non-exoelectrogenic (Escherichia coli), and a hydrogenotrophic methanogen (Methanosarcina barkeri) accomplished the feat but Geobacter was the fastest. Even cell debris and metalloproteins catalyzed HER. Therefore, living cells are not required for enhanced HER, and biocathodes could be a cheap and environmentally friendly alternative to precious metal catalysts. While the authors back then speculated on the role of metalloproteins, a new publication in Electrochimica Acta by researchers of Wageningen University shows that indeed trace metals in the growth medium are responsible for the observed rate acceleration.

The authors used a mixture of metal compounds present in the microbial medium such as cobalt, copper, iron, manganese, molybdenum, nickel and zinc salts as well as the metal chelating agent ethylenediaminetetraacetic acid (EDTA) as the catalyst for the HER under microbial compatible conditions (near-neutral pH, mesophilic temperature, aquous electrolyte).

They performed a series of experiments to investigate the effect of different parameters on the catalytic activity and stability of the trace metal mix medium. These parameters included the concentration of the metal compounds, the presence or absence of EDTA, the type of electrode material, and the type of electrolyte. Various techniques to measure the cathodic current, the hydrogen production rate, the overpotential, and the exchange current density of the HER were used.

The results show that the trace metal mix medium increased the cathodic current and the electron recovery into hydrogen significantly, and that copper and molybdenum were the most active compounds in the mix. This is surprising because the previous publication found mostly cobalt and iron compounds on the surface of the biocathodes. Both of which are good hydrogen catalysts as well, whereas molybdenum sulfide for example, did not increase production rates in methanogenic microbial electrolysis cells. HER is the rate determining reaction in methanogenic electrolysis cells because it is the intermediate:

4 H2 + CO2 → CH4 + 2 H2O

The results also showed that removing EDTA from the mix improved the catalyst performance further, as EDTA acted as a complexing (chelating) agent that reduced the availability of metal ions for HER. The results also showed that carbon-based electrodes were more suitable than metal-based electrodes for HER, possibly because they have a higher surface area. This is an interesting result because it was previously thought that the mechanism behind the better performance of carbon electrodes was the microbial preference to adhere to carbon than to metal surfaces. The results also showed that using microbial growth medium as the electrolyte did not affect the catalyst performance significantly, as compared to using phosphate buffer solution.

The authors concluded that their method was a simple, cheap, and environmentally friendly way to prepare effective catalysts for HER using trace metals from microbial growth media. They suggested that these catalysts could be integrated in biological systems for in situ hydrogen production in bio-electrochemical and fermentation processes. Indeed, it is inevitable not to use trace metals in microbial electrolysis cells as they are essential to sustain growth.

Both articles demonstrate that trace metals can play an important role in the HER, and that they can be derived from biological sources. However, they also have some limitations and challenges, such as the stability, selectivity, and scalability of the catalysts. Therefore, further research is needed to optimize the performance and applicability of trace metal-based catalysts for HER.

(Image: US National Science Foundation)