Fossil fuels have made tremendous social and economic advances pssible. This becomes clear, among other things, if you look at the increase in road traffic. Around 90 million vehicles were produced in 2019. In 2000 it was 60 million. It is assumed that the number of vehicles produced by 2030 will grow to 120 million. The increase in road mobility undoubtedly has a positive impact on social mobility and economic growth. However, this also makes the traffic increase a self-accelerating process. Economic growth in the Brics countries (Brazil, Russia, India, China and South Africa) is particularly crucial in this regard. At the same time, it is expected that the proportion of electric vehicles, including hybrids, will also increase sharply. However, whether this is realistic, given the limited lithium reserves, can again be doubted.

In 2010 more than 1 billion cars were registered worldwide. With an annual increase of around 3%, it was already 1.3 billion in 2019. These emit around 6.0 billion tons of CO2 annually (out of a total of 33 billion tons worldwide), making them the largest expanding source of CO2. Energy-related CO2 emissions are generally continuing to rise, although this increase was briefly interrupted by the global health crisis of 2020. In addition, there are 20 to 30% of emissions from the production of fuels and the manufacture and disposal of vehicles.

Life cycle analyzes of vehicles with different drive concepts are the subject of many studies. When it comes to CO2 emissions, the energy source is crucial. Two main developments are discussed today: the electrification of the propulsion system (i.e. fully and partially electrified vehicles) and the electrification of fuels (i.e. hydrogen and synthetic fuels).

In the manufacture of synthetic fuels, water is broken down into oxygen and hydrogen by electrolysis with renewable electricity. Due to the temporary oversupply of renewable electricity, this energy is particularly cheap. The hydrogen can then be used in hydrogen vehicles propelled by fuel cells. Alternatively, CO2 can be converted into hydrocarbons with hydrogen and then used in conventional combustion engines in a climate-neutral manner. The advantage of fuel cell vehicles is their high efficiency and the low cost of electrolysis. The disadvantage is the lack of a hydrogen infrastructure. Converting from hydrocarbons to hydrogen would cost trillions. The cheaper alternative would be synthetic hydrocarbons. However, the development is still in its infancy and the production of synthetic fuels cannot yet be carried out on a large scale.

Hydrogen and synthetic fuels are a necessary addition to electromobility, especially for long-distance and load transport. The widespread view that the low level of efficiency of internal combustion engines makes these fuels uninteresting ignores the possibility of using them to store and transport energy and to enable climate neutrality for air and shipping traffic. If you compare the CO2 emissions from electric motors and electrified fuels, it becomes clear that these mainly depend on the CO2 pollution of the electricity used.

Synthetic fuel sources

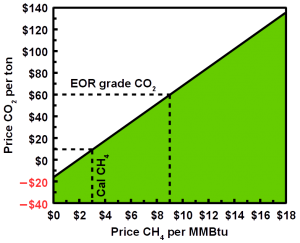

The production of synthetic fuel requires renewable electricity, water and CO2. The technical processes are known. However, the first large-scale industrial plants are only in the planning phase. However, pilot projects such as that of the Canadian company Carbon Engineering have shown the technical feasibility of scaling. The generation costs depend mainly on the size of the plant and the electricity price, which results from the local conditions, the structure of the electricity market and the share of renewable electricity.

The decentralized production of these fuels brings not only climate neutrality but also geopolitical gains. Since CO2 and renewable energy – in contrast to lithium – are generally accessible resources, users of this technology become independent of energy imports. At Frontis Energy we think these are strong arguments in favor of synthetic fuels.