Yeasts such as Saccharomyces cerevisiae are, as the name suggests, used for large scale production of beer and other alcoholic beverages. Their high salt and ethanol tolerance not only makes them useful for the production of beverages, but also suitable for the production of combustion fuels at high alcohol concentrations. Besides ethanol, long-chain fusel alcohols are of high interest for biofuel production as well. Bioethanol is already mixed with gasoline and thus improves the CO2 balance of internal combustion engines. This liquid biofuel is made from either starch or lignocellulose. The production and use of bioethanol supports local economies, reduces CO2 emissions and promotes self-sufficiency. The latter is especially important for resource-depleted landlocked countries.

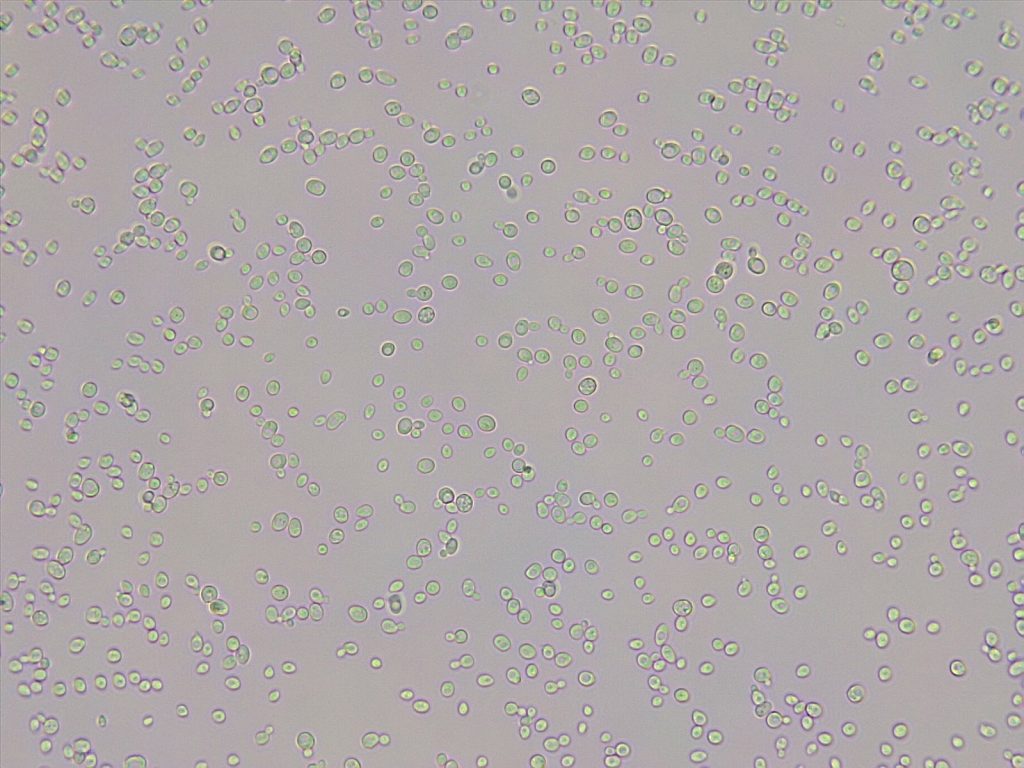

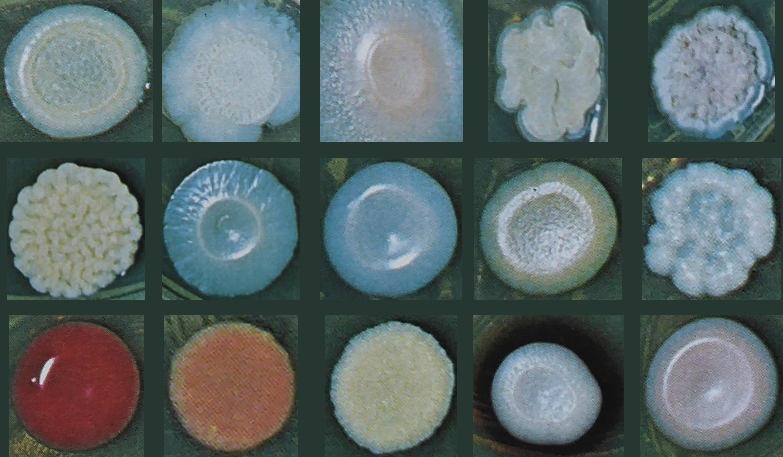

In order to efficiently produce ethanol and other alcohols from lignocellulose hydrolysates, yeasts must use both glucose and pentoses such as xylose and arabinose. This is because biomass is rich in both lignocellulose and thus glucose and xylose. However, this is also the main disadvantage of using Saccharomyces cerevisiae because it does not ferment xylose. Consequently, the identification of another yeast strains capable of fermenting both these sugars could solve the problem. Highly efficient yeasts can be grown in co-cultures with other yeasts capable of lignocellulose fermentation for ethanol production. Such a yeast is, for example, Wickerhamomyces anomalous.

To further improve ethanol production, bioelectric fermentation technology supporting traditional fermentation can be used. The microbial metabolism can thus be controlled electrochemically. There are many benefits of this technology. The fermentation process becomes more selective due to the application of an electrochemical potential. This, in turn, increases the efficiency of sugar utilization. In addition, the use of additives to control the redox equilibrium and the pH is minimized. Ultimately cell growth can be stimulated, further increasing alcohol production.

Such bioelectric reactors are galvanic cells. The electrodes used in such a bioelectric reactor may act as electron acceptors (anodes) or source (cathodes). Such electrochemical changes affect the metabolism and cell regulation as well as the interactions between the yeasts used. Now, a research group from Nepal (a resource-depleted landlocked country) has used new yeast strains of Saccharomyces cerevisiae and Wickerhamomyces anomalous in a bioelectric fermenter to improve ethanol production from biomass. The results were published in the journal Frontiers in Energy Research.

For their study, the researchers chose Saccharomyces cerevisiae and Wickerhamomyces anomalus as both are good ethanol producers. The latter is to be able to convert xylose to ethanol. After the researchers applied a voltage to the bioelectrical system, ethanol production doubled. Both yeasts formed a biofilm on the electrodes, making the system ideal for use as a flow-through system because the microorganisms are not washed out.

The researchers speculated that the increased ethanol production was due to the better conversion of pyruvate to ethanol − the yeast’s central metabolic mechanism. The researchers attributed this to accelerated redox reactions at the anode and cathode. The applied external voltage polarized the ions present in the cytosol, thus facilitating the electron transfer from the cathode. This and the accelerated glucose oxidation probably led to increased ethanol production.

Normally, pyruvate is converted into ethanol in fermentation yeast. External voltage input can control the kinetics of glucose metabolism in Saccharomyces cerevisiae under both aerobic and anaerobic conditions. Intracellular and transplasmembrane electron transfer systems play an important role in electron transport across the cell membrane. The electron transfer system consists of cytochromes and various redox enzymes, which confer redox activity to the membrane at certain sites.

The authors also found that an increased salt concentration improved conductivity and therefore ethanol production. The increased ethanol production from lignocellulosic biomass may have been also be due to the presence of various natural compounds that promoted yeast growth. When the cellulose acetate membrane was replaced by a Nafion™ membrane, ethanol production also increased. This was perhaps due to improved transport of xylose through the Nafion™ membrane as well as the decrease of the internal resistance. A further increase of ethanol production was observed when the bioelectrical reactor was operated with fine platinum particles coated on the platinum anode and neutral red deposited on the graphite cathode.

At Frontis Energy, we think that the present study is promising. However, long-chain fusel alcohols should be considered in the future as they are less volatile and better compatible with current internal combustion engines. These can also be easily converted into the corresponding long-chain hydrocarbons.