Zinc-air batteries are a promising alternative to expensive lithium-ion batteries. Compared with lithium-ion technology, zinc-air batteries have a greater energy density, very low production cost, and superior safety. However, their fundamental inability to recharge has lowered their wide-scale adoption.

Zinc-air batteries use charged zinc particles to store large amounts of electricity at a time. When electricity is required, the charged zinc is combined with oxygen from the air (and water), releasing the stored electricity and producing zincate. This process is known as oxygen reduction reaction (ORR).

Theoretically, this zincate can again be broken down into oxygen and zinc ions by passing electricity through it. This process, in turn, is called oxygen evolution reaction (OER). Using these reactions, zinc-air batteries can be made rechargeable, competing with lithium-ion batteries.

The major challenge of the recharging process is the sluggish kinetics of the reactions which lead to poor cycle life. These batteries require a catalyst that could potentially enhance the ORR and the OER reactions, making their kinetics fast. Hence, the development of highly efficient catalysts is of paramount importance for rechargeable zinc-air batteries.

Previous studies have suggested transition-metal oxides as great bifunctional ORR / OER catalysts because of their ability to provide sites for the reversible adsorption of oxygen. But the methods involved in creating well-defined defects for reversible adsorption of oxygen in such oxides are challenging.

To investigate the use of cobalt(II) oxide nanosheets deposited on stainless steel or carbon cloth as a bifunctional catalyst, a group of researchers from different universities of China and Canada collaborated and conducted several experiments. Their research findings were published in the journal Nano Energy .

Research approach

Preparation of catalyst

Different nano-structures were prepared using simple heat treatment and electrodeposition to test them as bifunctional electrocatalysts. The type of nano-structures prepared were:

-

-

- Cobalt hydroxide nanosheets on steel and carbon cloth

- Layered cobalt (II) oxide nanosheet on steel and carbon cloth

- Cobalt (II) oxide on steel

- Layered cobalt tetroxide nanosheet on steel

-

Material Characterization

To understand the characteristics of the prepared samples, various analyticaland tests were carried out:

- Studying the chemical morphology of the samples using a scanning electron microscopy and a transmission electron microscopy. The oxygen vacancies in the samples were confirmed by X-ray photo electron spectroscopy and X-ray absorption near-edge structure and extended X-ray absorption fine structure.

- Study of surface chemistry using atomic force microscopy and other equipment. To draw correlations between the oxygen vacancy defects and intrinsic ORR / OER activity linear sweep voltammogram of the samples were investigated in a three-electrode electrochemical cell.

Charging and discharging tests

Later discharge and charge cycling tests of single cells were operated by the battery testing system.

Results

The simple heat treatment strategy created oxygen vacancy sites. According to the authors, layered cobalt-oxide nano-sheets exhibited excellent bifunctional ORR / OER performance. Investigations suggested abundant oxygen vacancies and cobalt sites be the reason for enhanced ORR / OER performance. Later, the developed layered cobalt-oxide nanosheets on steel were used as an electrode in a rechargeable zinc-air flow battery and a record-breaking cycle life of over 1,000 hours with nearly unchanged voltage was observed. Galvanostatic discharging-charging cycles also demonstrated long life and high energy efficiency.

This research carried out provides a new method to design highly efficient bifunctional ORR / OER catalysts that could be used to enhance the cycle life of rechargeable zinc-air flow batteries. At Frontis Energy we are looking forward to industrial applications.

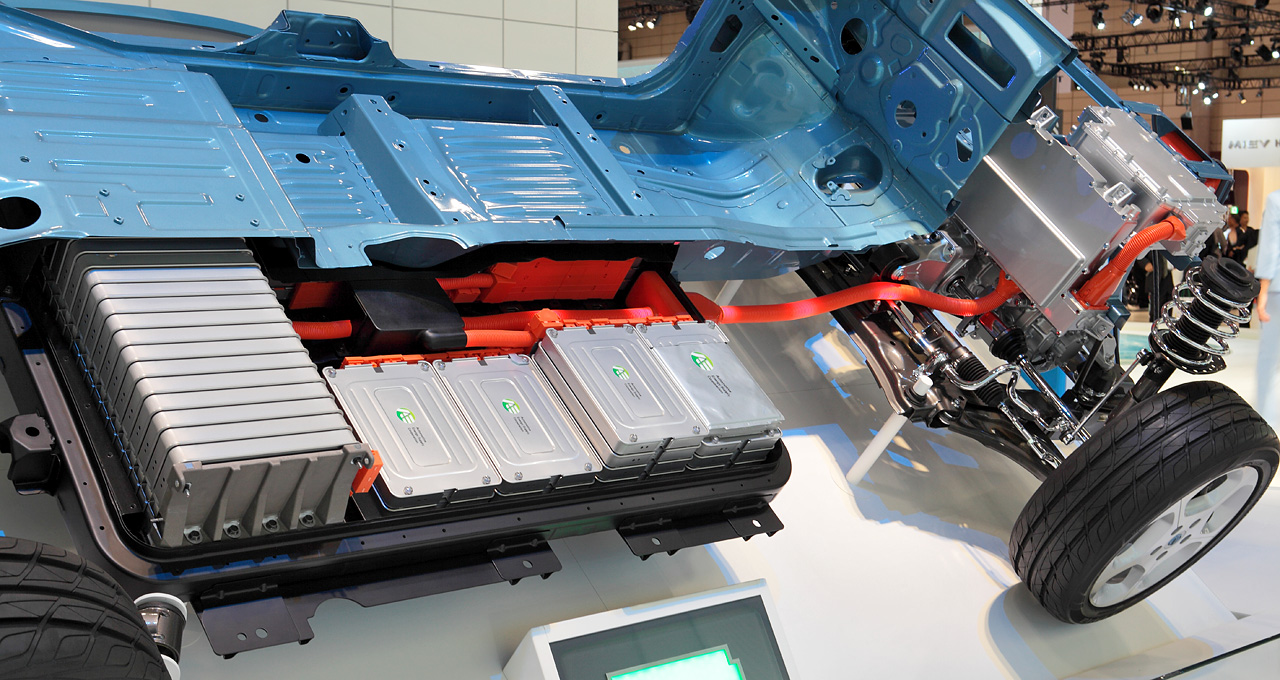

(Photo: Engineersforum)

Reference: https://doi.org/10.1016/j.nanoen.2020.105409 Wu et al., Cobalt (II) oxide nanosheets with rich oxygen vacancies as highly efficient bifunctional catalysts for ultra-stable rechargeable Zn-air flow battery, 2021